- Home

- Products

- About Us

- Blog

- Contact Us

Regenerative Thermal Oxidation (RTO) is a common technology used for air pollution control in various industrial processes. RTO is used to treat volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted from industrial processes.

The RTO process involves the combustion of VOCs and HAPs at high temperatures (up to 1500 degrees Fahrenheit) in the presence of excess oxygen. The combustion process converts these pollutants into carbon dioxide and water vapor, which are then released into the atmosphere.

| No | Item | Parameter |

| 1 | RTO Double bed Seies | 5000-150000 Nm³/h |

| 2 | RTO Three bed Seies | 5000-150000 Nm³/h |

| 3 | RTO Five bed Seies | 15000-250000 Nm³/h |

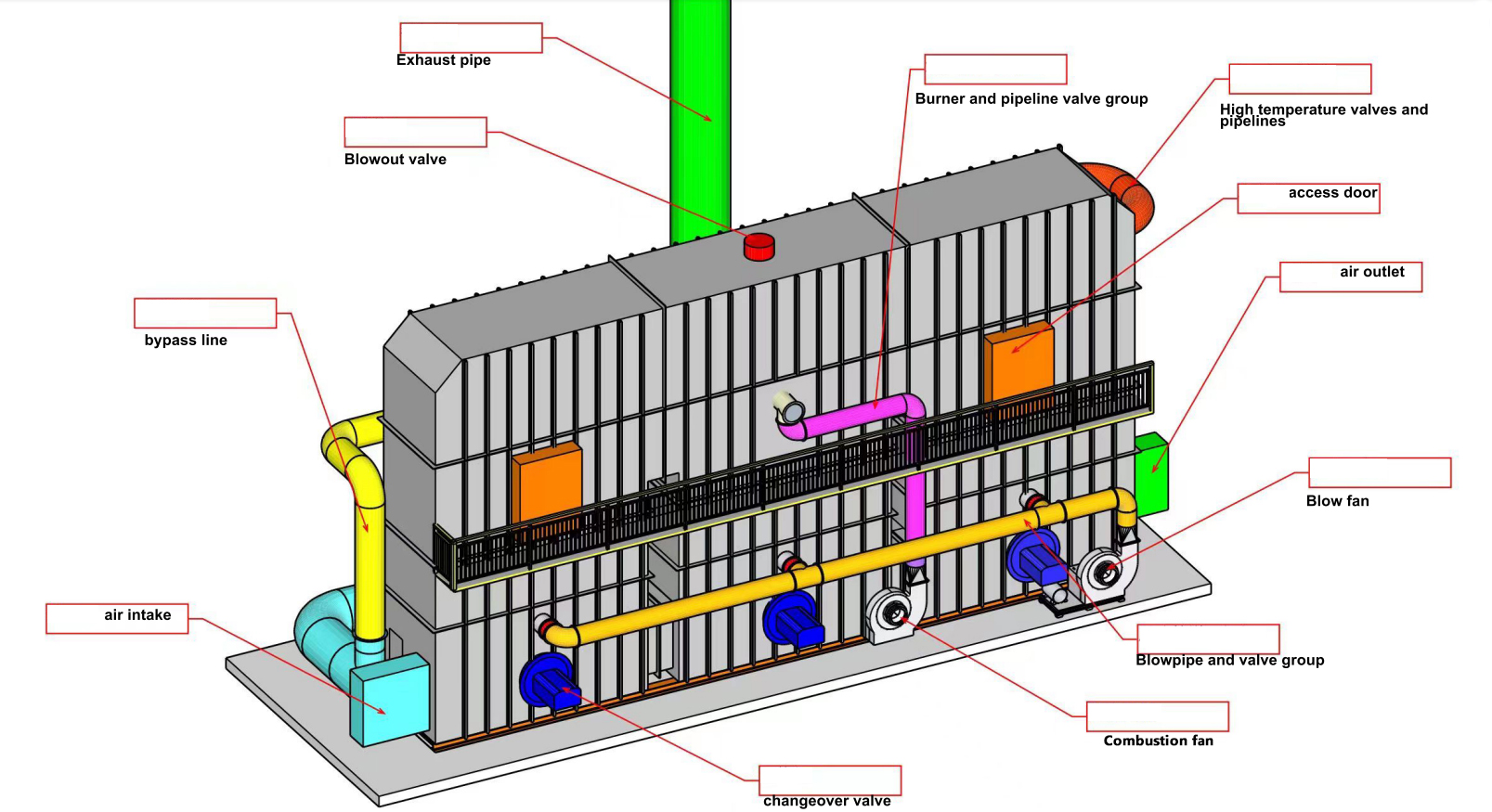

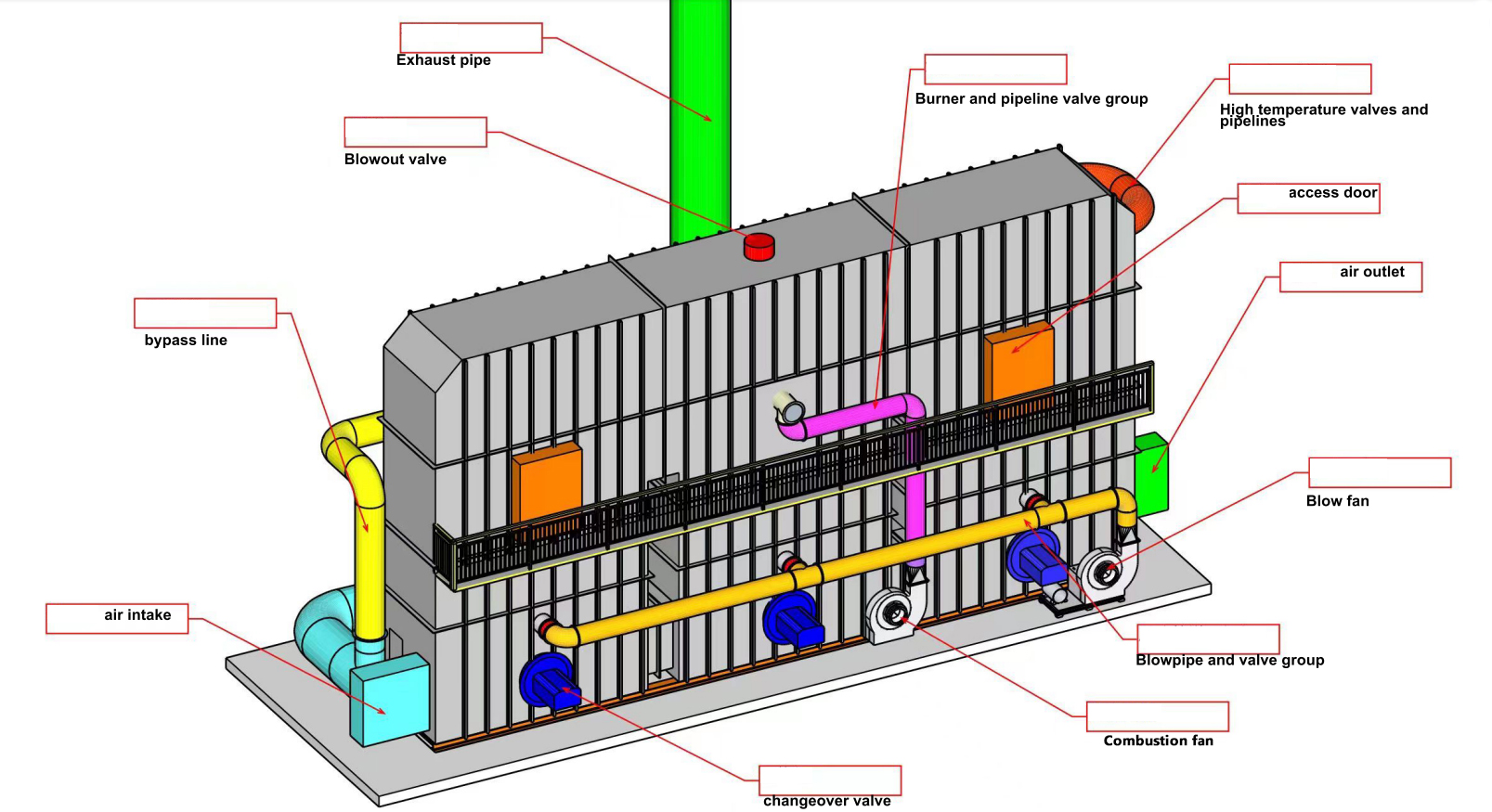

Flow chart of Regenerative Thermal Oxidation Production Line

1. Uniform design of airflow distribution

The air flow enters the heat storage bed evenly to ensure the heat exchange efficiency of the heat storage bed.

2. Selection of high-quality refractory materials

The refractory material is a folded block of ceramic fiber cotton with a temperature resistance of up to 1260 degrees, and the surface is sprayed with a hardener to form a hardened layer of silica film to fix the fibers on the inner wall.

3. High-quality low-NOx burner

The system uses natural gas, liquefied petroleum gas, and national standard diesel as the fuel system.The burner is equipped with a sight glass to clearly observe the flame of the main fire, and the ultraviolet flame scanner detects the flame state at any time.

4. Independently developed and produced ceramic regenerator

Improve heat transfer efficiency and reduce RTO system resistance.

5. High quality switching valve group

Double sealing surface switching valve group and safety actuator, the number of switching times without failure is not less than 1 million times, and it is equipped with valve position safety detection.

6. Multi-point temperature detection of ceramic bed

The ceramic bed adopts a multi-point temperature detection system to ensure the safe operation of the RTO through a PLC closed-loop system.

7. Original multi-bed multi-layer temperature correction

In the normal operation of RTO, due to the difference of pipeline resistance and ceramic bed, the heat accumulation effect will cause temperature deviation, and the temperature deviation correction system can automatically adjust and balance the system temperature.

8. Reliable operation safety design

Multi-point continuous detection and emergency emptying system.

9. Unique internal self-cleaning system

It has a safe and reliable burnout device to ensure the self-cleaning of the internal ceramic materials in working condition.

10. Efficient heat recovery system

A heat exchange system is installed downstream, which can make full use of the heat discharged from the RTO and convert it into hot water, hot air, hot oil, etc. for reuse.

Regenerative Thermal Oxidation Air Purification System (RTO) is a mature exhaust gas purification equipment. The system has high operational reliability, easy operation and low maintenance cost, and has attracted widespread attention.It is typically used in the iron printing and coating industry, paint and ink manufacturing, textile and chemical electronics industries. It is specially used to treat volatile organic waste gas (VOC). Volatile organic solvents (VOCs) in the exhaust gas are decomposed and oxidized into carbon dioxide and water in a high-temperature environment.It is considered to be the most economical and environmentally friendly treatment device with universal applicability and durability.

●Applicable to the concentration and composition of various industrial waste gases

●Wide range of air volume for waste gas treatment

●Using a special heat exchange system to improve the recycling of internal heat

●It can achieve the best exhaust gas purification efficiency and meet the strict exhaust gas emission standards of all countries in the world

●Extremely high cost performance

The working principle of RTO involves multiple steps, including the adsorption phase, combustion phase, and purging phase. During the adsorption phase, the exhaust gas passes through one of the ceramic beds, where VOCs are adsorbed onto the media. Once the bed is saturated, the process switches to the combustion phase. The VOC-laden bed is isolated, and a burner heats the media to a temperature sufficient to oxidize the pollutants. The combustion gases release heat, raising the bed temperature. The purified gas is then released to the atmosphere. In the purging phase, the other ceramic bed is activated to capture VOCs while the first bed regenerates through purging with clean air. The process alternates between the two beds, ensuring continuous operation.

Q: Are there any legal requirements for industries to implement RTO systems?

A: Yes, many countries have environmental regulations that mandate the use of RTO or similar technologies to control air pollution from industrial processes.

Q: How does RTO compare to other air pollution control technologies?

A: RTO offers higher destruction efficiency and lower operating costs compared to many other technologies, making it an attractive option for many industries.

Q: Can RTO handle emissions from hazardous substances?

A: Yes, RTO is capable of treating emissions containing hazardous substances and VOCs effectively.

Q: How long does it take to recover the initial investment in an RTO system?

A: The payback period varies depending on factors like the scale of the operation and the local regulatory environment, but many companies see a return on investment within a few years.

Q: Can RTO systems be retrofitted into existing industrial processes?

A: Yes, RTO systems can often be retrofitted into existing facilities, providing an efficient and sustainable solution to update pollution control measures.

Regenerative Thermal Oxidation (RTO) is a common technology used for air pollution control in various industrial processes. RTO is used to treat volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted from industrial processes.

The RTO process involves the combustion of VOCs and HAPs at high temperatures (up to 1500 degrees Fahrenheit) in the presence of excess oxygen. The combustion process converts these pollutants into carbon dioxide and water vapor, which are then released into the atmosphere.

| No | Item | Parameter |

| 1 | RTO Double bed Seies | 5000-150000 Nm³/h |

| 2 | RTO Three bed Seies | 5000-150000 Nm³/h |

| 3 | RTO Five bed Seies | 15000-250000 Nm³/h |

Flow chart of Regenerative Thermal Oxidation Production Line

1. Uniform design of airflow distribution

The air flow enters the heat storage bed evenly to ensure the heat exchange efficiency of the heat storage bed.

2. Selection of high-quality refractory materials

The refractory material is a folded block of ceramic fiber cotton with a temperature resistance of up to 1260 degrees, and the surface is sprayed with a hardener to form a hardened layer of silica film to fix the fibers on the inner wall.

3. High-quality low-NOx burner

The system uses natural gas, liquefied petroleum gas, and national standard diesel as the fuel system.The burner is equipped with a sight glass to clearly observe the flame of the main fire, and the ultraviolet flame scanner detects the flame state at any time.

4. Independently developed and produced ceramic regenerator

Improve heat transfer efficiency and reduce RTO system resistance.

5. High quality switching valve group

Double sealing surface switching valve group and safety actuator, the number of switching times without failure is not less than 1 million times, and it is equipped with valve position safety detection.

6. Multi-point temperature detection of ceramic bed

The ceramic bed adopts a multi-point temperature detection system to ensure the safe operation of the RTO through a PLC closed-loop system.

7. Original multi-bed multi-layer temperature correction

In the normal operation of RTO, due to the difference of pipeline resistance and ceramic bed, the heat accumulation effect will cause temperature deviation, and the temperature deviation correction system can automatically adjust and balance the system temperature.

8. Reliable operation safety design

Multi-point continuous detection and emergency emptying system.

9. Unique internal self-cleaning system

It has a safe and reliable burnout device to ensure the self-cleaning of the internal ceramic materials in working condition.

10. Efficient heat recovery system

A heat exchange system is installed downstream, which can make full use of the heat discharged from the RTO and convert it into hot water, hot air, hot oil, etc. for reuse.

Regenerative Thermal Oxidation Air Purification System (RTO) is a mature exhaust gas purification equipment. The system has high operational reliability, easy operation and low maintenance cost, and has attracted widespread attention.It is typically used in the iron printing and coating industry, paint and ink manufacturing, textile and chemical electronics industries. It is specially used to treat volatile organic waste gas (VOC). Volatile organic solvents (VOCs) in the exhaust gas are decomposed and oxidized into carbon dioxide and water in a high-temperature environment.It is considered to be the most economical and environmentally friendly treatment device with universal applicability and durability.

●Applicable to the concentration and composition of various industrial waste gases

●Wide range of air volume for waste gas treatment

●Using a special heat exchange system to improve the recycling of internal heat

●It can achieve the best exhaust gas purification efficiency and meet the strict exhaust gas emission standards of all countries in the world

●Extremely high cost performance

The working principle of RTO involves multiple steps, including the adsorption phase, combustion phase, and purging phase. During the adsorption phase, the exhaust gas passes through one of the ceramic beds, where VOCs are adsorbed onto the media. Once the bed is saturated, the process switches to the combustion phase. The VOC-laden bed is isolated, and a burner heats the media to a temperature sufficient to oxidize the pollutants. The combustion gases release heat, raising the bed temperature. The purified gas is then released to the atmosphere. In the purging phase, the other ceramic bed is activated to capture VOCs while the first bed regenerates through purging with clean air. The process alternates between the two beds, ensuring continuous operation.

Q: Are there any legal requirements for industries to implement RTO systems?

A: Yes, many countries have environmental regulations that mandate the use of RTO or similar technologies to control air pollution from industrial processes.

Q: How does RTO compare to other air pollution control technologies?

A: RTO offers higher destruction efficiency and lower operating costs compared to many other technologies, making it an attractive option for many industries.

Q: Can RTO handle emissions from hazardous substances?

A: Yes, RTO is capable of treating emissions containing hazardous substances and VOCs effectively.

Q: How long does it take to recover the initial investment in an RTO system?

A: The payback period varies depending on factors like the scale of the operation and the local regulatory environment, but many companies see a return on investment within a few years.

Q: Can RTO systems be retrofitted into existing industrial processes?

A: Yes, RTO systems can often be retrofitted into existing facilities, providing an efficient and sustainable solution to update pollution control measures.